Shop

-

Hornady American Whitetail Ammunition 6.5 Creedmoor 129 Grain Interlock Spire Point Box of 20

Hornady designed and tailored the American Whitetail line of ammunition just for the Whitetail Deer hunter. This ammunition line is loaded with the legendary Interlock bullet at conventional velocities in the most popular bullet weights for taking down the buck of a lifetime. Hornady has combined a generation of ballistic know-how and combined that knowledge with modern components and manufacturing excellence to create a line of ammunition that will deliver the consistent accuracy and performance that they have built their reputation upon.

The Hornady InterLock bullet is designed to be a devastating hunting bullet and nothing less. The InterLock Ring, a Hornady exclusive, ensures that the hard-alloyed lead core and tapered jacket remain locked together during expansion. The resulting bullet retains more mass, energy and momentum after impact and transfers that energy into the target. It is this reliable stopping power that has earned the InterLock a worldwide reputation as a bullet for the serious hunter. This ammunition is new production, non-corrosive, in boxer primed, reloadable brass cases.

CAD $39.44 -

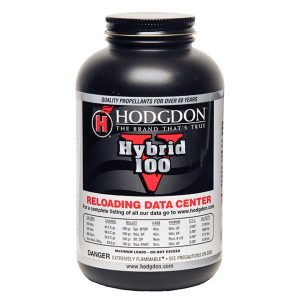

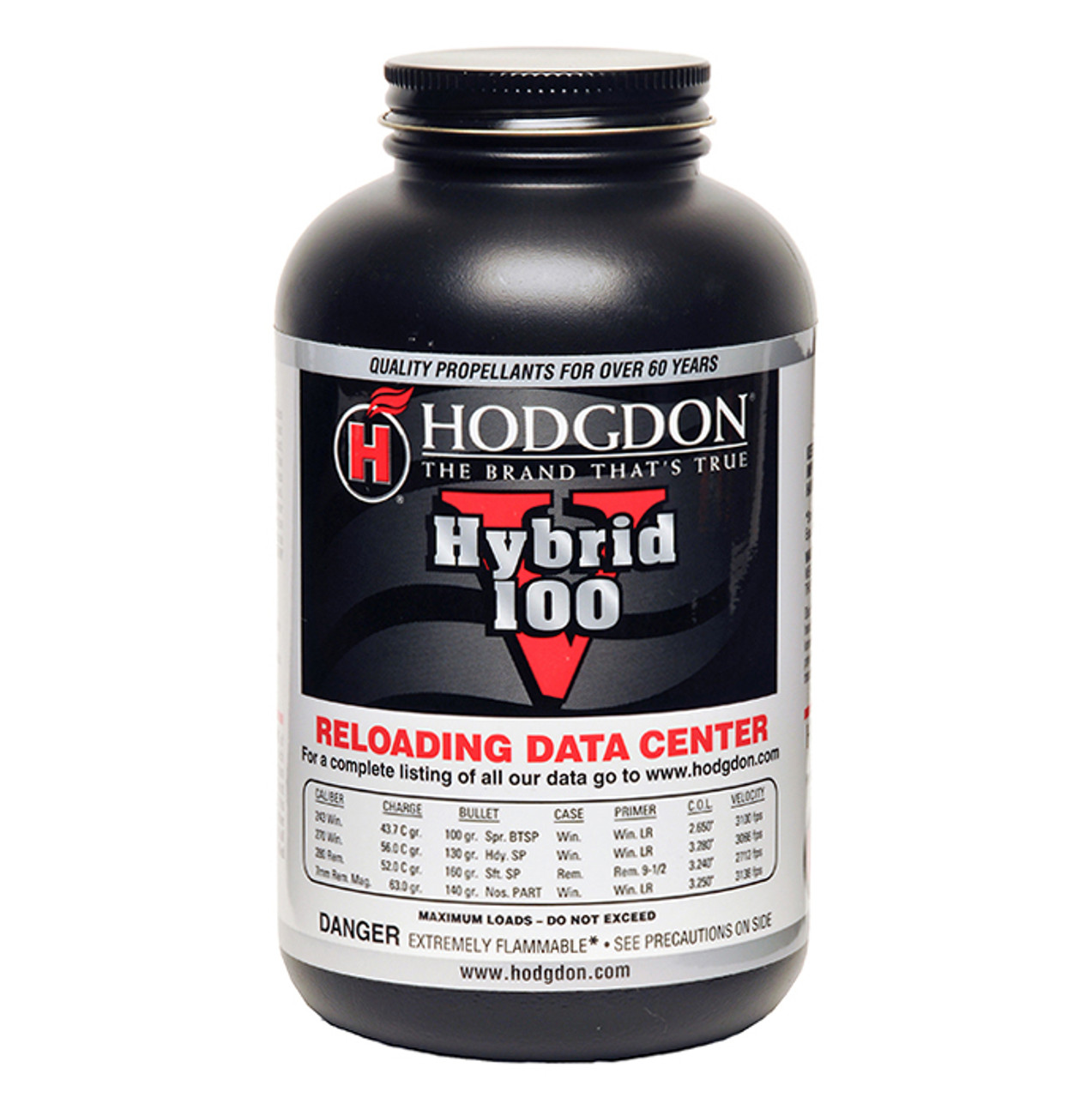

Hodgdon Hybrid 100V

Product Overview

CAD $59.83 – CAD $441.99 -

Winchester Brass 25-35 WCF Bag of 50

Winchester makes the highest quality brass available, and each and every piece is made to meet and exceed the most demanding quality control and performance standards in the industry. New, unprimed brass. This is not loaded ammunition.

Preparation:

- Due to the manufacturing process and/or shipping, case mouths may not be perfectly round. To ensure a round case mouth, cases must be sized (or have the expander ball of the sizing die run through case neck) and deburred/Chamfered prior to loading.

Note:

- A light “staining” may be found on the case neck of new brass. This is due to annealing. Annealing is a process, performed by the manufacturer, which involves rapid heating to a specified temperature followed by rapid cooling. This process imparts cases with the proper hardness to securely hold a bullet as well as gives flexibility to expand and contract upon firing and repeated forming. The “staining” is a residue from this process. This stain may be removed by tumbling before loading. Brass should be full-length sized, trimmed and chamfered before loading.

CAD $47.25Winchester Brass 25-35 WCF Bag of 50

CAD $47.25 - Due to the manufacturing process and/or shipping, case mouths may not be perfectly round. To ensure a round case mouth, cases must be sized (or have the expander ball of the sizing die run through case neck) and deburred/Chamfered prior to loading.

-

Quality Cartridge Brass 32-40 Winchester Box of 20

Quality Cartridge started in 1990 manufacturing custom, obsolete and wildcat cartridge cases. Quality Cartridge uses the highest quality materials and equipment to produce the best brass available. Along with the high quality of their products Quality Cartridge also properly head stamps over 450 different calibers from popular wildcats to obsolete cartridges. It is easy to see why Quality Cartridge has become the go-to source for obscure cartridge needs.

Because of variations in case size for some specialty cartridges, it is best to check the brass against a fired case from a particular firearm to ensure suitability. Whenever possible, brass has been formed to published standards for the cartridge. This is not loaded ammunition.

Brass Preparation: With bulk rifle brass you may sometimes notice a few case mouths are “out of round” or slightly dented below the shoulder. These imperfections occur in the final tumbling wash operation after the case mouth has been annealed. Brass manufacturers are aware of the case cosmetics and have worked to mitigate it, but due to equipment design, denting may still occur. Minor dents are normally removed in the first firing and will not affect case life or performance. On non-plated brass, you may also notice all the anneal stain might not be polished off, which may give the case neck a pinkish color. With some smaller caliber cases you may notice the case mouths to be slightly belled.

With all new rifle brass, you should first straighten out the case and case mouth, then chamfer and debur the case mouth inside and out. To straighten the case mouth, run the case part way into the sizer die and let the expander ball straighten the brass. To prevent the case neck from stretching, be sure to lubricate the case neck inside the case mouth.

CAD $46.00 -

Lapua Brass 223 Remington Box of 100

Lapua World-class brass begins with high-quality raw materials and superior smelting and metallurgical competence. Throughout the production process, the focus on quality control is consistent with Lapua’s exacting standards. Particular attention is paid to hardness, solidity and grain structure. All Lapua brass is tested to 30% overpressure according to Commission Internationale Permanente, the agency that oversees ammunition and component producers in Western Europe. This is not loaded ammunition.

Brass Preparation: With bulk rifle brass you may sometimes notice a few case mouths are “out of round” or slightly dented below the shoulder. These imperfections occur in the final tumbling wash operation after the case mouth has been annealed. Brass manufacturers are aware of the case cosmetics and have worked to mitigate it, but due to equipment design, denting may still occur. Minor dents are normally removed in the first firing and will not affect case life or performance. On non-plated brass, you may also notice all the anneal stain might not be polished off, which may give the case neck a pinkish color. With some smaller caliber cases you may notice the case mouths to be slightly belled.

With all new rifle brass, you should first straighten out the case and case mouth, then chamfer and debur the case mouth inside and out. To straighten the case mouth, run the case part way into the sizer die and let the expander ball straighten the brass. To prevent the case neck from stretching, be sure to lubricate the case neck inside the case mouth.

CAD $84.00Lapua Brass 223 Remington Box of 100

CAD $84.00 -

Hornady Brass 9.3x62mm Mauser Box of 50

Hornady produces brass with the same precision, attention to detail and focus on perfection that has made them a world leader in bullets. They measure their brass for consistent wall concentricity, tests pressure calibration to ensure uniform case expansion and hand-inspects each piece.

This dedication to quality ensures proper seating of the bullet both in the case and in the chamber and consistent charges and pressures. The result is optimal velocity and repeatable accuracy from your cartridges. New, unprimed brass. This is not loaded ammunition.

Brass Preparation: With bulk rifle brass you may sometimes notice a few case mouths are “out of round” or slightly dented below the shoulder. These imperfections occur in the final tumbling wash operation after the case mouth has been annealed. Brass manufacturers are aware of the case cosmetics and have worked to mitigate it, but due to equipment design, denting may still occur. Minor dents are normally removed in the first firing and will not affect case life or performance. On non-plated brass, you may also notice all the anneal stain might not be polished off, which may give the case neck a pinkish color. With some smaller caliber cases you may notice the case mouths to be slightly belled.

With all new rifle brass, you should first straighten out the case and case mouth, then chamfer and debur the case mouth inside and out. To straighten the case mouth, run the case part way into the sizer die and let the expander ball straighten the brass. To prevent the case neck from stretching, be sure to lubricate the case neck inside the case mouth.

CAD $62.00Hornady Brass 9.3x62mm Mauser Box of 50

CAD $62.00 -

Hornady Brass 416 Rigby Brass Box of 20

Hornady produces brass with the same precision, attention to detail and focus on perfection that has made them a world leader in bullets. They measure their brass for consistent wall concentricity, tests pressure calibration to ensure uniform case expansion and hand-inspects each piece.

This dedication to quality ensures proper seating of the bullet both in the case and in the chamber and consistent charges and pressures. The result is optimal velocity and repeatable accuracy from your cartridges. New, unprimed brass. This is not loaded ammunition.

Brass Preparation: With bulk rifle brass you may sometimes notice a few case mouths are “out of round” or slightly dented below the shoulder. These imperfections occur in the final tumbling wash operation after the case mouth has been annealed. Brass manufacturers are aware of the case cosmetics and have worked to mitigate it, but due to equipment design, denting may still occur. Minor dents are normally removed in the first firing and will not affect case life or performance. On non-plated brass, you may also notice all the anneal stain might not be polished off, which may give the case neck a pinkish color. With some smaller caliber cases you may notice the case mouths to be slightly belled.

With all new rifle brass, you should first straighten out the case and case mouth, then chamfer and debur the case mouth inside and out. To straighten the case mouth, run the case part way into the sizer die and let the expander ball straighten the brass. To prevent the case neck from stretching, be sure to lubricate the case neck inside the case mouth.

CAD $69.00Hornady Brass 416 Rigby Brass Box of 20

CAD $69.00 -

Hornady Brass 257 Weatherby Magnum Box of 50

Hornady produces brass with the same precision, attention to detail and focus on perfection that has made them a world leader in bullets. They measure their brass for consistent wall concentricity, tests pressure calibration to ensure uniform case expansion and hand-inspects each piece.

This dedication to quality ensures proper seating of the bullet both in the case and in the chamber and consistent charges and pressures. The result is optimal velocity and repeatable accuracy from your cartridges. New, unprimed brass. This is not loaded ammunition.

Brass Preparation: With bulk rifle brass you may sometimes notice a few case mouths are “out of round” or slightly dented below the shoulder. These imperfections occur in the final tumbling wash operation after the case mouth has been annealed. Brass manufacturers are aware of the case cosmetics and have worked to mitigate it, but due to equipment design, denting may still occur. Minor dents are normally removed in the first firing and will not affect case life or performance. On non-plated brass, you may also notice all the anneal stain might not be polished off, which may give the case neck a pinkish color. With some smaller caliber cases you may notice the case mouths to be slightly belled.

With all new rifle brass, you should first straighten out the case and case mouth, then chamfer and debur the case mouth inside and out. To straighten the case mouth, run the case part way into the sizer die and let the expander ball straighten the brass. To prevent the case neck from stretching, be sure to lubricate the case neck inside the case mouth.

CAD $88.00Hornady Brass 257 Weatherby Magnum Box of 50

CAD $88.00 -

Starline Brass 44 Russian

Starline Brass prides itself on producing the highest quality brass case available. Their brass is comprised of 70% copper and 30% zinc and is vertically drawn during the manufacturing process which results in more uniform wall thickness. Cases are annealed between each draw to ensure consistent metallurgy in all lots. Each brass case is hand inspected to guarantee the highest quality possible.

Starline Brass is located in Sedalia, MO and has been in business for over 30 years. Trust Starline for your next reloads, you won’t be disappointed. New, unprimed brass. This is not loaded ammunition. Bulk brass should be full-length sized, trimmed and chamfered before loading.

Brass Preparation: With bulk rifle brass you may sometimes notice a few case mouths are “out of round” or slightly dented below the shoulder. These imperfections occur in the final tumbling wash operation after the case mouth has been annealed. Brass manufacturers are aware of the case cosmetics and have worked to mitigate it, but due to equipment design, denting may still occur. Minor dents are normally removed in the first firing and will not affect case life or performance. On non-plated brass, you may also notice all the anneal stain might not be polished off, which may give the case neck a pinkish color. With some smaller caliber cases you may notice the case mouths to be slightly belled.

With all new rifle brass, you should first straighten out the case and case mouth, then chamfer and debur the case mouth inside and out. To straighten the case mouth, run the case part way into the sizer die and let the expander ball straighten the brass. To prevent the case neck from stretching, be sure to lubricate the case neck inside the case mouth.

If you are using Nickel plated brass, special care must be taken to lubricate the cases prior to sizing them. Nickel plating is harder than brass and the cases require more effort in sizing. In the event a case becomes stuck, purchase a stuck case remover; don’t use pliers, screwdrivers or other common household tools which could damage your sizing die.

CAD $36.00Starline Brass 44 Russian

CAD $36.00 -

Federal Premium Gold Medal Large Rifle Match Primers #210M Box of 1000 (10 Trays of 100)

The same quality primers that make Gold Medal cartridges the choice of match shooters and hunters everywhere. Federal Gold Medal Primers are manufactured to exacting tolerances and use Federal’s exclusive basic lead styphnate priming mix of optimum primer ignition.

CAD $148.50 -

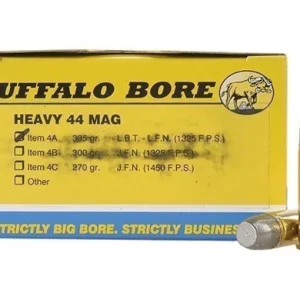

Buffalo Bore Ammunition 44 Remington Magnum 305 Grain Lead Long Flat Nose

Buffalo Bore Heavy ammunition is loaded with the highest quality components to produce great accuracy and performance. From powder to bullet selection this load is made to be one of the best defense loads available. This ammunition is safe to fire in any steel frame revolver or rifle chambered in 44 Remington Magnum that is in safe working condition. This ammunition is new production, non-corrosive, in boxer primed, reloadable brass cases.

Owner of Buffalo Bore Tim Sundles on Heavy 44 Magnum Ammunition:

Item 4A (305gr. Hard Cast gas Checked LFN) is designed for super deep penetration on large game. The big flat nose keeps the bullet penetrating straight and thus deep. You can expect a good three + feet of penetration. The flat nose also does considerably more damage than a round nosed type of bullet as the flat nose cuts and smashes it way through living matter, while round nosed bullets tend to slip and slide through matter, doing much less damage along the bullet’s path and achieving more shallow penetration due to getting sideways while slipping and sliding through matter.

You’ll note my below velocities from over-the-counter revolvers and rifles.

- Ruger Bisley cut down to 6 inches——1328 fps

- Ruger Red Hawk 5.5 inch—————–1331 fps

- Marlin 1894 18.5 inch———————-1779 fps

Item 4A is recommended for all STEEL revolvers and rifles on today’s market. It is not suitable for scandium or aluminum alloy revolvers.

CAD $73.44 -

Buffalo Bore Ammunition Outdoorsman 357 Magnum 180 Grain Lead Flat Nose Gas Check Box of 20

Buffalo Bore loads their ammunition with the highest quality components available to maximize the performance of the ammunition. This ammunition is safe to use in all 357 Magnum chambered firearms with steel frames that are in proper working condition. This ammunition is new production, non-corrosive, in boxer primed, reloadable brass cases.

Owner of Buffalo Bore Tim Sundles on Buffalo Bore Heavy 357 Magnum Ammunition:

Our 357 mag. ammo adds more power than ever before to the 357 mag. This ammo is safe to shoot in ANY all steel 357 revolver – this includes J frames. This ammo is no harder on your gun than any other normal 357 ammo. Please don’t phone us and ask if this ammo is safe in your gun. It is, providing your gun is in safe condition for use with any normal 357 ammo.

We don’t recommend this ammo to be fired in super light alloy revolvers as bullets may jump crimp under recoil, but the ammo itself wont hurt these super light weight revolvers. These revolvers are simply so light that the recoil is severe enough to cause crimp jump.

The below velocities are offered so that you can see what guns/barrel lengths give what velocities with this new 357 mag. ammo. You’ll notice that new S&W revolvers with short barrels are often shooting faster than older S&W revolvers with longer barrels. The new S&W revolvers are very good and are made with equipment that makes them more consistent and faster than the S&W revolvers of yesteryear.

1. 3 inch S&W J frame

- 19A/20-180gr. Hard cast LFN = 1302 fps

2. 4 inch S&W L frame Mt. Gun

- 19A/20-180gr. Hard cast LFN = 1375 fps

3. 5 inch S&W model 27

- 19A/20-180gr. Hard Cast =1398 fps

4. 18.5 inch Marlin 1894

- 19A/20-180gr. Hard Cast = 1851 fps

CAD $55.76 - 19A/20-180gr. Hard cast LFN = 1302 fps